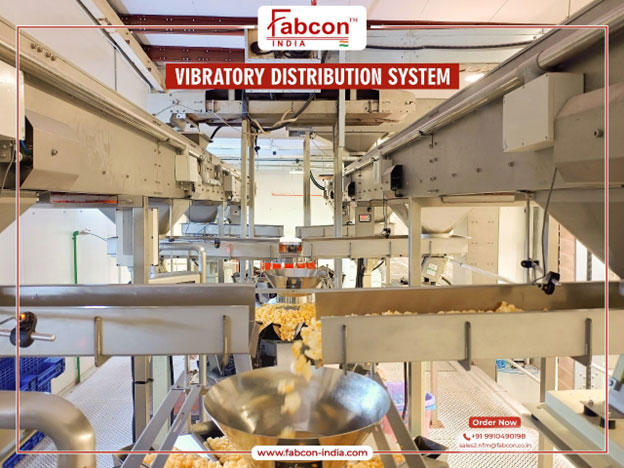

Feeding multiple weigher with 2 sets of product by using 2 distribution systems.. gives more flexibility.

A system that vibrates components or materials along a track or trough is known as a vibratory-controlled feeding system. The system comprises a track or trough, a control unit, and a vibratory feeder. A tray or bowl that vibrates at a high frequency makes up the vibratory feeder.

The components or materials move down the track or trough as a result of the vibration. To regulate the flow rate and guarantee that the components or materials are fed at a constant pace, the vibration’s amplitude and frequency can be changed.

In manufacturing and assembly processes, vibratory-controlled feeding systems are frequently used to feed components to a production line. In general, vibratory-controlled feeding systems are very effective, and they may be tailored to fit the unique requirements of a variety of applications.

Products can flow through manufacturing more rapidly when conveyors are used, which helps to satisfy increased demand. Moreover, it is necessary to carry out the tasks of storing, sorting, orientating, assigning, placing, and inserting promptly, safely, and without causing any harm to the goods.